|

Where to begin

Whatever size of shower area you intend to

create, there is always one constant - you need to get the water

away. So we begin with the drainage component. You

simply need to decide where you wish to place your linear drain and how long

the gully will be.

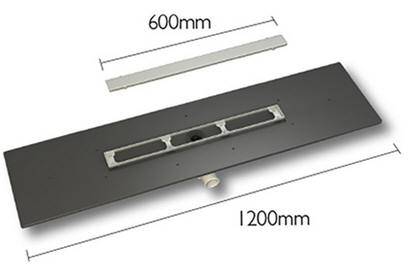

The VARI DECK drainage

component

This is the central element of the

modular wet-floor system and can be trimmed on site to size. The

drainage component is available with 1, 2 or 3 outlet traps

that can achieve a flow rate of up to 68 l/m, and with a choice

of gully grills from 600mm to 2000mm wide.

The drainage component (as supplied) is

1200mm x 300mm. This can however be trimmed according to

requirements. The 1200mm length can be reduced to 660mm (minimum)

and the 300mm depth reduced to 220mm (minimum) if a wall drain

configuration is required.

Gully length

When placing the drainage component and

gully in proximity to a wall you have a choice of two positions

- against the wall or set away from the wall.

You can choose how long the gully will

be. You might for example want a smallish grill to be visible

when finished, or you might require the grill to extend all the

way across an alcove from wall to wall.

With this modular system the choice is

yours. Gullies are available in 15 standard sizes from 600mm to

1500mm, and up to 2000mm in custom made sizes! If one of the

standard sizes is not suitable then a

Fast-track bespoke manufacturing service is available.

|

|

|

The

drainage component is supplied 1200mm

long and 300mm wide, but can be trimmed

according to requirements. In the event that you

require a gully longer than the drainage

component, the wings of the gully simply extend

beyond. |

|

Grill (gully cover) type

The drainage gully has a cover or grill.

This is what you will see when your wet room shower is finished.

As with all other components in this range you have a choice.

You can choose to have a cover which can

be

|

Grill options |

|

|

|

1. Solid stainless steel

(G1) |

2. rebated to allow a tile

to be inserted (G3) |

|

|

|

|

Special order

grills |

|

|

|

3. Stainless steel with

square holes |

4. Slotted stainless steel |

|

|

|

5. frameless, making it

near invisible |

|

|

The slope to the gully

Once the location of the drain component

is determined, it is a simple case of creating the slope in the floor to the gully using tapered boards.

The tapered boards are manufactured

using a high density UPS core with a mineral coating making them

lightweight and easy to handle, whilst retaining good thermal

properties and compressive strength. The thicker (outer) edge of

the board is 22mm (the same as a standard flooring board) with a

pre-engineered gradient to 11mm (where it meets the drainage

component).

Tapered boards (that can be used

singly or in conjunction with others to create a larger

shower area) can be trimmed easily on site for a perfect fit.

|