|

Introduction

Booster pumps are widely used

to enhance the performance of a shower. Not all

people like to have water hurled at them at high velocity,

though some prefer to feel as though they've been blasted with a

pressure washer. While there may be some sort of sadomasochistic

force at work with the bigger models, power shower pumps

range in performance and at the entry level offer a means to

turn a disappointing dribble into a worthy event. As

pressure and flow rates increase so does the enjoyment of having your

skin massaged with jets of water. Whatever it is for you

there are a few simple yet important factors to take into

account otherwise you may end up regretting your investment.

|

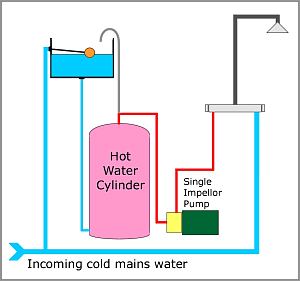

This is where the supply to

the pump emanates from a header tank (also known as a

cistern) often sited in the loft. It is in contravention of

Water Bye Laws to try and increase the performance (pressure

or flow rate) of a system directly fed from the rising main.

More specifically...

If you have a mains pressure

hot and/or cold water system you may not add a pump

in an attempt to make it more powerful (this is why you

should be mindful of your supply pressure and flow rate when

opting for a mains pressure system. You do not have the

option of boosting supplies should you subsequently discover

they're not to your satisfaction.)

|

|

Back to the top

You must not attempt to

increase performance by adding a pump ahead of the boiler

(to increase incoming pressure and flow which is fed

directly from the main) or after the boiler to enhance

output (this won't work and it is in contravention of Bye

Laws being a mains fed device). As the boiler is already

working at maximum output there is little point trying to

make it work harder.

Furthermore...

Booster pumps are designed to

take a 'low pressure' feed and boost it. The pressures that

can build up in a mains supply (especially at night when

water demand is typically low) can be high and are likely to

blow seals. Connecting your pump to a mains supply will

invalidate its warranty.

A gravity water system (that's

one fed from a header tank) is the ONLY type of water system

to which you may fit a booster pump. For various reasons you

may not fit a pump to any other sort of system. Installing a

booster pump to a gravity supply will normally increase the

water pressure substantially, but you should consider what

sort of pump to buy carefully based on your shower equipment

and more importantly... your expectations.

Back to the top

|

Many households have to deal

with what we shall call a 'split system'. This is where hot

water is supplied under gravity pressure and all the cold

water outlets are at mains pressure. In the old days when a

separate tap dealt with each you wouldn't necessarily have

noticed. But nowadays it is very common to find mixer

showers in many bathrooms and this is where a problem begins

to manifest itself. |

|

When you supply a shower mixer

valve with unequal pressures you may experience difficulty

controlling the output temperature. This can be due to the

overwhelming nature of the mains pressure cold supply in

comparison to the relatively weak supply of gravity hot

water.

Water has a single objective -

to find the easiest route out. So when the higher pressure

cold water hits the shower valve it is presented with a

choice - to exit via the valve and handset or go back up the

hot water pipe (which can often be the easier option). You

can probably appreciate if the latter happens you won't get

any hot water.

Attempts are made to cure this

problem by simply boosting the pressure of the hot water.

Logically one might consider this a sensible option.

Although there is nothing wrong with boosting just the

gravity supply it frequently fails to address the problem

fully. The reason? You need to consider what happens when

you open the shower valve. (The diagram to the right

illustrates such a setup) |

|

|

When both feeds (H & C) to the

shower valve are pumped gravity supplies the shower pump

recognises an initial pressure drop or flow of water

as the valve is opened and responds by energising the pump.

However, when the cold water is at mains pressure, the

moment you open the valve the more boisterous cold supply

muscles it's way back along the hot water pipe (seeing this

route as an easy way out) and confuses the pump sensor.

Being unable to recognise valid start up conditions the pump

fails to energise.

It must be said that a twin

impellor pump with a gravity hot and cold supply is by far

the best solution, but if you have been lumbered with the

split system you can get it to work by being a bit tricky

yourself.

You need to protect the

pump/hot water feed from the initial surge of cold water

entering the shower valve. To do this you might try opening

the shower flow control while the temperature dial is fully

in the 'hot' position. This should prohibit cold water from

entering the valve when you initially open it and allow the

hot water flow hence activating the pump. Once activated the

pump will continue to run as you introduce your cold water

to the mix. You should however be very careful! It is

essential that you return the shower valve temperature

control to a comfortable level immediately after the pump

energises. Forgetfulness or failure to do so could result in

scalding.

It is stressed this is not a

recommended fix, it is a way to cheat the system. It is

potentially risky, could result in injury and may not work

in all scenarios. It is recommended you do the job properly

and install a twin impellor pump.

Split or mixed systems are not recommended.

Back to the top |

The ratings by which

manufacturers sell their pumps can be confusing. After all,

when looking at two different pumps each rated at 1 bar

('bar' is the unit by which pressure is expressed. It is

equivalent to 1 atmosphere, 14.5 psi or the pressure that would be

generated by a water tower if it were 33 feet in height)

what is the difference? Why should one be more expensive

than the other?

Bar pressure is only one

component of a water delivery system. It is important to

take into account another crucial factor when examining pump

performance.... the amount of water the pump can deliver

(usually expressed in 'litres per

minute') at the stated pressure. This is known as the

'flow rate'.

For example: 18 litres per

minute (18 l/m or

18 lpm) at 1 bar.

You should not get carried

away by the fact that a pump can simply produce high

pressure. An example of this might be

the little pressure washers you can buy at hardware stores

for cleaning patios, cars, windows etc. These are often

rated at quite phenomenal pressures (1000-1500 psi or pounds

per square inch). Pressure like this could injure you if you

were to direct the blast at your skin. Whilst high pressure,

these little units actually only shift a very small amount

of water. Compare them to the blast from a fire engine hose

- at much lower pressure a fire hose can knock a man off his

feet. This is because of the volume of water combined with a

moderate pressure. The fire engine by maintaining a very

high flow rate at a moderate pressure produces impressive

force/performance.

This, together with certain

other factors, is why one shower pump might cost

more than another.

In defence of pump

manufacturers, specifying what a pump might be able to do is

complicated by another variable - what you are feeding the

water through. For example: A pump feeding water down a hose

at 2 bar without having a nozzle on the end will surely get

your garden wet but you will notice that the water runs

rather than blasts out. Now put your finger over the end of

the open hose pipe and you'll feel pressure build. At the

same time the previously mundane flow becomes a powerful jet

that can reach quite some distance.

Without going into this

further, it is this principal a shower handset exploits -

lots of small holes creating back pressure through which

water is forced. Different handsets will have different

sized holes, some will have multiple spray patterns. This is

why it's so difficult to be exact about how a particular

pump will perform - it's all relevant to what you hook it up

to.

If you have a 'watering can'

or 'deluge' type shower head you cannot expect the same

invigorating performance you might get from a handset. Using

the above example, you are creating less back pressure

because the larger holes in the head are arranged across a

wider area and may be more numerous. This configuration will

get you very wet but you may not get the powerful force you

were hoping for.

Back to the top

Most shower booster pumps

operate by the same principle. Low pressure water is taken

into a chamber and fed into the centre of an impellor which

is spinning quickly. The water is effectively thrown outward

by centrifugal force and ejected from the impellor housing

at high speed. The amount of water that the impellor can

move determines the flow rate, the force that the impellor

can maintain relates to the pressure. A pump typically has

one or two impellors, depending on whether it is deemed

'single' or 'twin'. Impellors are driven by a motor (usually

electric). A twin impellor pump will often have an impellor

located at either end of the electric motor's armature

(motor positioned centrally).

The power that the motor can

generate will be proportionate to the resulting pressure and flow rate

achievable. A twin impellor pump usually takes a hot and

cold low pressure feed and boosts them simultaneously. A

single impellor pump is suitable for a hot, a cold or a blended

low pressure supply. Most shower pumps are set up to sense

when you open your shower valve and activate automatically.

Similarly, they switch off automatically when you close your

shower valve.

This is a term that you may

have come across but misunderstanding still exists to

exactly what it all means.

In a nutshell, the difference

between the two is determined by whether the header tank is

above or below the outlet point. If the header tank is above

you have a positive head. If it's below the outlet you have

a negative head.

In a gravity water system it

goes without saying that water will only travel in the

direction of gravity - downward. For this reason some people

believe that if you take water down from the loft to a

ground floor hot water cylinder, then back up to a first

floor bathroom that water is indeed having to go up hill and

that a negative head scenario exists. In this example this

would be an incorrect conclusion. It is the relative

position of the header tank to the outlet point. If the

header in the loft is higher than the outlet point then a

positive head exists even though the water travelled down to

the ground floor before going back up to the outlet.

If indeed the outlet is higher

than the header tank and a negative head exists you will

require what's known as a negative head set up.

In a negative head scenario

things kind of happen in reverse. When you open your shower

valve (or outlet - which could be a tap) water would rather

run backward down the pipe to the header tank. SO... if you

want your pump to activate automatically it needs to be

equipped with a different type of sensor. Negative head

pumps can usually be recognised by a canister that

piggybacks the pump. This is part of the sensing system -

not needed on positive head pumps. Alternatively, some

manufacturers supply (as optional extras) what they call a

'negative head kit' or a 'manual negative head kit'. In

reality this kit is nothing more than a manual means of

switching on a standard booster pump when water is required

at an outlet above the header tank. The negative head kit

typically comprises a 'momentary contact' pull chord which

energises the pump. Once running the pump will continue

pushing water up to the outlet until closed, at which time

the pump will turn off - ready for the next manual

activation.

Back to the top

Other things to know about

power shower pumps.

Apart from

bar pressure and flow rate there is one other fairly major

consideration. Is the pump rated for constant or

intermittent use? Some manufacturers dress this up with

words like 'regenerative', but at the end of the day it all

means the same thing. A pump will either run continuously or

it needs to rest after about 10-15 minutes of use (for about

45 minutes to cool down). If you happen to be a household

where mum, dad and all the children like to use the same

shower one after the other, and the typical shower time will

be from 5-10 minutes, then a pump with intermittent rating

simply won't suffice. When such a pump has been in operation

for it's prescribed time it will simply cut out (so that it

may cool down). Many an unwary owner has thought their

shower pump to be faulty when in fact it is doing what it

needs to do. So, select a pump with a duty cycle that will

match in with your requirements.

We

mentioned in an earlier paragraph about pressure and flow

rate. Focussing on flow rate you should ascertain the size

of the pipe connections on your proposed purchase. Shower

booster pumps typically have either 15mm or 22mm pipe

connections. A 22mm pipe has the capacity to transport twice

the amount of water than a 15mm will carry. The size of

connection is therefore a bit of a give-away as to the

pump's capability. It is not generally considered a good

idea to try installing a pump with 22mm connections into a

system where the rest of the pipework is 15mm.

Back to the top

As mentioned, both the hot and

cold feeds to a booster pump need to be gravity pressure

supplies. The cold water feed can either be a dedicated cold

supply direct from the header tank, or as is often the case,

by teeing into the cold water feed to the hot water

cylinder. Cold is simple enough. The hot water feed to the

pump needs a little more consideration.

The normal hot water draw-off

point is typically at the top of a hot water cylinder -

right at the top, dead centre. If you simply pull your hot

water from this point you may end up with a problem.

The reason: Hot water releases

minute air bubbles. Ordinarily these rise to the top of the

cylinder and vent out through the header tank in the loft.

If you try taking water at the point where the bubbles are

leaving the cylinder you are likely to pull them into the

pump when it's running. This can cause a condition known as

cavitation. In a nutshell, a big bubble of air forms at the

low pressure zone ahead of the pump impellor. The condition

can cause damage to the pump and will almost certainly

generate some weird and wonderful noises - including

squealing and banging!

The solutions:

1) If you intend to keep the

present hot water cylinder you should consider using either

a 'Surrey' or 'Essex' flange. This device screws into the

top of the cylinder and creates two outlets. One becomes the

normal outlet/vent, the other (being the shower take-off

point) draws hot water from slightly lower in the cylinder,

hence allowing the bubbles to pass on by.

2) If you intend to change the

cylinder for any reason then make sure the new one has a

dedicated shower take-off point. This will do the job of a

flange type device. Shower take-offs shouldn't make the

cylinder any more expensive, but you must ask for one to be

fitted as they are not normally included.

Click here for

more info on cylinders.

Back to the top

You might really like the experience associated with a

powerful blast of water when taking a shower. Some people

don't feel clean unless they feel a layer of skin has been

removed during the event! But don't lose sight of how

quickly you are emptying your water storage vessels as you

shower.

A boosted shower will empty

your system quicker. The bigger and more powerful the pump

the quicker the system will empty. If you simply add a pump

to your existing system you run the risk of potentially

running it dry unless you do a few calculations. It is

actually quite difficult to be precise with this because of

various factors (how much water for example does your shower

head deliver?). You will need to make certain guesstimations.

The amount of water a shower pump will deliver will even be

affected by how big the holes are in the shower head, and

how many there are! Some how you need to calculate how big

the header tank in the loft must be in order to provide an

average of 10 minutes shower time. Yes, some people

(especially teenagers) stand in the shower for longer, so

you must either make provision for this or re-educate users.

Some people find a timer on the show

it use. Whatever you do and however you choose to do it,

make sure you don't run your pump dry - this can cause it

irreparable damage.

The

materials from which a pump is manufactured will invariably

influence the cost of the pump, but with good reason. Cheap

shower pumps rely heavily on plastics in their construction.

Whilst there is nothing wrong with plastics technology it

happens to be a fact that pumps made mainly from plastic

don't last as long as their more expensive counterparts.

Pumps considered to be 'top end' products tend to be

constructed from metal - especially the impellor housings

that are often made of brass. It can often be a false

economy to buy a cheap pump as the brass-bodied models can

outlast them several times over.

Back to the top

A noisy pump can

annoy you or drive you to despair! Pumps produce vibrations.

This is a fact that cannot be ignored or negated. If you are

looking for a vibration-free silent booster pump don't waste

your time. Some pumps will vibrate more than others. You can

probably guess that cheap pumps utilising cheaper materials

and made with less refined manufacturing techniques are

likely to vibrate more than their more expensive cousins.

As mentioned, vibration is the

culprit. Quality materials and accurately machined

components will minimise vibration and therefore noise

output but will not get rid of it entirely. It is important

to consider the transmission of vibration which is where the

noise comes from.

Manufacturers of the more

expensive brands of pump recognise this as a major issue.

Pumps are therefore made from quality materials such a

brass, motors are often of the 'induction type' that run

more quietly and the foot upon which the pump stands is

designed to absorb vibration - minimising transmission into

the surrounding area.

Apart from all the operational reasons that will

determine the most appropriate location for your pump, there

is the issue of vibration. Even the quietest most expensive

pumps will vibrate when in operation. It is therefore of

paramount importance that you consider well how and where to

put your little noise generator.

Place a shower booster pump

directly on a timber floor and you might as well stand it on

the sound box of a guitar. By it's hollow nature the guitar

sound box amplifies small vibrations from the strings so you

can hear them (by contrast a solid bodied electric guitar

needs an amplifier or it can't be heard). A hollow wooden

floor behaves in exactly the same way - amplifying

vibrations. Don't do it - the noise could drive you crazy!

Whenever possible you should

choose a location and/or stand your pump on materials where

transmission of vibration is minimised. A small pad stone,

maybe some sort of sandwich including rubber or polystyrene

leaves might be considered a suitable way to insulate

yourself from vibrations. Experiment but make sure the pump

will be secure.

Don't be surprised if having

ignored this advice you experience problems.

Back to the top

Think in terms of where in

your system you intend to install your booster pump. Plan

things out before committing yourself to pipework. Never

forget that anything connected to the outboard side (the

boosted side) of the pump will cause the pump to activate

when used. To illustrate this point here follows an example

of how you may prefer not to do things...

A typical household decide to

up the performance of their gravity fed shower, so install a

3 bar shower booster pump next to the hot water cylinder in

the airing cupboard. Having done so, their shower became

quite a beast and gave an exhilarating experience to all who

used it.

One night the lady of the

house was awoken in the small hours by a thunderous noise.

She jumped out of bed in a panic to find out what on earth

the racket could be. She was surprised to bump into her

young daughter who was returning to her bedroom having been

to the toilet. "What on earth has happened?" asked the mum.

The daughter replied "I don't know, I've just been to the

toilet and flushed it." Upon investigation it transpired

that the plumber had fitted the twin impellor shower pump in

such a position that all water feeds to their bathroom were

now boosted. As the daughter flushed the toilet it activated

the booster pump. What was worse, the pump had been

positioned on the hollow floor in the airing cupboard which,

in the dead of night, sounded like a steam train thundering

through the house. It was subsequently discovered that not

only the shower and toilet been boosted, so too had the bath

and the wash basin. So, open a tap and the pump came on!

This story is absolutely true.

It highlights the very real considerations of installing a

pump and where you should insert it in your plumbing system.

If you only wish to boost the shower then make sure that's

all that is connected to the output of the pump. (Remember

to site it on something quite too!)

Back to the top |